FACILITIES +

TECHNOLOGY

FACILITIES +

TECHNOLOGY

Our dry ice production plants are characterized by the need for no hydraulic drive. Only in the world a new electromechanical drive allows the production of high quality dry ice and high compression (1.5 – 1.56 g / cm³).

The production works completely without hydraulic oil. There is no longer a need for expensive and preventive measures that protect dry ice from contamination with hydraulic oil.

Our installations (TRIPLE-ICE102 EMD and TWIN-ICE102 EMD) transform carbon dioxide into dry ice with a very high conversion rate of up to 45%. It is a high quality dry ice production with very efficient CO2 to dry ice conversion. Thanks to the electromechanical drive a production of dry

ice which is quite usable around food is possible.

DRY

ICE

DRY ICE

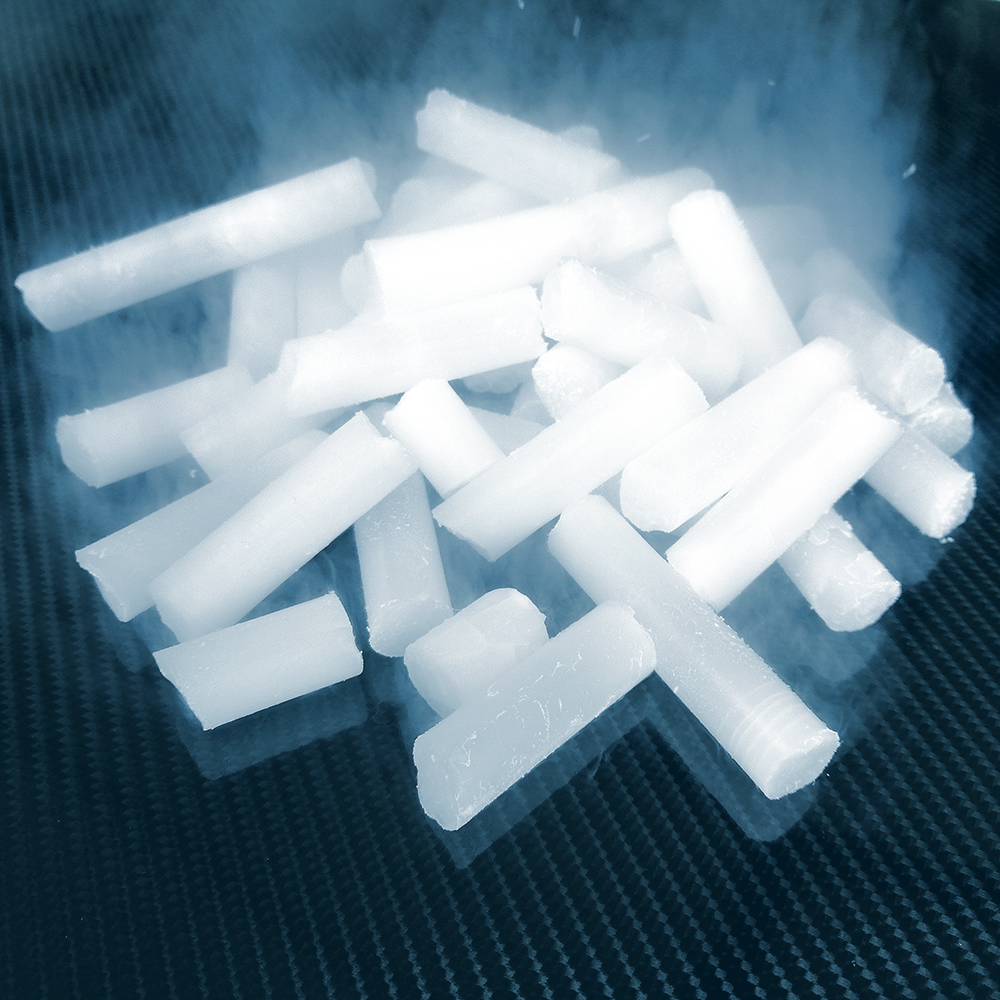

Dry ice is produced from liquid CO2 which expands and cools under a pressureless condition. In this condition the CO2 snow – dry ice – breaks down. This ice can be pressed into slices, blocks or granules.

The advantages of dry ice are:

- Direct vaporization: Dry ice does not melt, but transforms from a hard state into a gaseous state. In other words, there is nothing left compared to the vaporization of normal ice cream (no water!)

- The force of cooling is three times higher in comparison with that of normal ice

- Dry ice has neither odour nor flavour

- Dry ice slows down bacterial multiplication

- Dry ice is not toxic. It is incombustible and inert

Thanks to these characteristics dry ice has many uses. It is excellent for the refrigeration of food and pharmaceutical products. In addition, dry ice can be used for medical applications. The chemical industry makes use of heat dissipation. Dry ice is also used for cleaning. It is a non-abrasive cleaning, completely without rubbing or sharpening.

Sectors of dry ice use:

- Air catering

- Catering and delivery of food for further processing (B2B)

- Pharmaceutical and chemical industry, medical technology

- Industrial cleaning

- Online commerce with food (B2C)

ADVANTAGES

ADVANTAGES

Our dry ice production facilities are electromechanically rotated. This renunciation of a hydraulic driving force means that the production of dry ice takes place completely without hydraulic oil. In this way the dry ice is not likely to be contaminated with oil as well as there is no risk of hydraulic hoses which can crack.

With our facilities we can produce high quality dry ice with a high density (1.5 – 1.56 g / cm³) which can be used around food. This use is a decisive objective of CRYONCO GmbH & Co. KG.

Professional programming allows Remote Control by computer, laptop or tablet as well as Remote Support. The installations of CRYONCO GmbH & Co. KG have a modular architecture which makes them adjustable to the wishes of the customers.

The recovery of carbon dioxide during the production of dry ice is immense. Up to 95% of the carbon dioxide can be recovered, that is, much less carbon dioxide emissions are required during the production of dry ice than other times.

Regarding sustainable management, a big step forward is the use of organic carbon dioxide.

Our advantages are:

- Electromechanical force

- Without hydraulic power

- Without hydraulic oil

- Can be used around food

- High density of the conversion of carbon dioxide into dry ice

- A single snow compartment without screws

- Bass sound power

- Remote Control + Support possible

- Modular architecture

- Reduced carbon dioxide emission

- High recovery of carbon dioxide

- Organic carbon dioxide as a perspective

SUSTAINABILITY

SUSTAINABILITY

Our new dry ice production facilities have been developed in constant dialogue with our customers.

CRYONCO GmbH & Co. KG values this dialogue very much which facilitates further development.

Here we are aware that CO2 is one of the causes of the greenhouse effect. This awareness is an important driver of our improvement efforts. It should be noted that the CO2 used to produce dry ice is obtained from combustion and exhaust gases or is obtained as bio-CO2 in the production of biomethane gas. It is therefore not produced separately.

By using recovery technology, which is highly recommended, an optimized recovery rate of 95% of the CO2 used in the production of dry ice is achieved with CryonCo systems. We try to do justice to the sustainability and responsibility concerns of our living environment through a constant recycling process.

ABOUT US

ABOUT US

CryonCo GmbH & Co. KG is an innovative start-up based in Horb in the Black Forest.

We work closely with competent and experienced long-term production and sales partners such as Comtecswiss.

We would be happy to design a dry ice system precisely tailored to your needs. We will install this

system for you and provide regular maintenance for trouble-free operation.

Just ask us.

Our innovative and sustainable technology will convince you.

We look forward to your contact.